ROVER WHEELS: Monitoring changes over time, NOTE: Read back through the thread to avoid repeating misconceptions |

ROVER WHEELS: Monitoring changes over time, NOTE: Read back through the thread to avoid repeating misconceptions |

May 16 2013, 08:35 AM May 16 2013, 08:35 AM

Post

#1

|

||

|

Junior Member   Group: Members Posts: 22 Joined: 10-August 12 From: Australia Member No.: 6530 |

[MOD NOTE: This thread follows on a post by Ed Truthan containing a MAHLI mosaic of MSL wheels taken on sol 275.]

Ed: zooming in on that marvellous underbelly MAHLI montage, there appears to be further (and previously noted) deformation of the wheel surfaces. Damage is most evident in the view of the front-left wheel inner surface. Such wear has previously been discussed and concerns allayed. Nevertheless, the front left wheel surface *appears* to have been punctured. We've only done 700 meters, and have 7000 more to get to Mt Sharp..... Given that more odometry has now accumulated, is any (re-)new(ed) concern valid? DeanM |

|

|

|

||

|

May 16 2013, 10:15 AM May 16 2013, 10:15 AM

Post

#2

|

|

Senior Member     Group: Moderator Posts: 2262 Joined: 9-February 04 From: Melbourne - Oz Member No.: 16 |

No, I wouldn't be concerned.

Yes there is a bit of damage, yes there will be 10x as much when we get to Mt Sharp, but the wheels will still be fine to drive on, this was expected. -------------------- |

|

|

|

May 16 2013, 11:12 AM May 16 2013, 11:12 AM

Post

#3

|

|

|

Forum Contributor     Group: Members Posts: 1372 Joined: 8-February 04 From: North East Florida, USA. Member No.: 11 |

Your going to have to regularly reassure us.....it looks bad to the layman. Of course at least the wheels can be regularly photographed as MSL roves accross this amazing landscape

|

|

|

|

May 16 2013, 02:05 PM May 16 2013, 02:05 PM

Post

#4

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

|

|

|

|

May 16 2013, 02:56 PM May 16 2013, 02:56 PM

Post

#5

|

|

Senior Member     Group: Members Posts: 1465 Joined: 9-February 04 From: Columbus OH USA Member No.: 13 |

Isn't the "puncture" merely a glint of light? Could there be anything on Mars hard enough to make a narrow puncture through that much metal?

-------------------- |

|

|

|

May 16 2013, 03:03 PM May 16 2013, 03:03 PM

Post

#6

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

If the rover is still roving, such reassurance is utterly redundant. That's a nice empirical observation. Somewhere in a review package I expect there's a detailed analysis of how the wheel was designed, with allowable levels of damage, predicted damage and margins. I haven't seen that package and if I had, I couldn't post the details anyway. So any assurance I could offer on this forum wouldn't really be fact-based, but I assume the designers had it under control. Over on nasaspaceflight.com someone proposed a drinking game based on how many times this comes up -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

May 16 2013, 03:06 PM May 16 2013, 03:06 PM

Post

#7

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

Could there be anything on Mars hard enough to make a narrow puncture through that much metal? I won't speculate on these images, but the wheels are pretty thin (I don't know what the actual number is) and the loads can be pretty high on a sharp rock. Aluminum isn't that hard. -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

May 16 2013, 03:13 PM May 16 2013, 03:13 PM

Post

#8

|

|

Senior Member     Group: Members Posts: 4247 Joined: 17-January 05 Member No.: 152 |

the front left wheel surface *appears* to have been punctured. We've also discussed this before. I still see no clear sign of puncture. The dents may be reflecting bits of bright sky which makes it look like there are punctures.About reasurrances, it would be interesting to hear from someone who knows something about the engineering of the wheels. Does the thin skin covering the circumference of the wheels, which is dented, actually provide significant structural strength to the wheels? Or does the skin just prevent sand and dust from getting into the wheel mechanisms inside, and the raised, narrow, treads are actually providing the main structural strength? In this case the skin could be severely punctured and torn and we could still drive. Edit: scooped by Joe, and thanks mcaplinger for the details. |

|

|

|

May 16 2013, 03:59 PM May 16 2013, 03:59 PM

Post

#9

|

|

Senior Member     Group: Members Posts: 1619 Joined: 12-February 06 From: Bergerac - FR Member No.: 678 |

QUOTE The dents may be reflecting bits of bright sky which makes it look like there are punctures. It can't be. We are seeing these things in shadow, and from where there are, impossible to have the sky in sight. Because of the wheel itself, and the rover body. I'm wondering about the material used to build theses wheels. At first, I thought they where designed in the exact same way as the MER's : a metalic monobloc. -------------------- |

|

|

|

May 16 2013, 05:33 PM May 16 2013, 05:33 PM

Post

#10

|

|

Senior Member     Group: Members Posts: 4247 Joined: 17-January 05 Member No.: 152 |

Being in shadow means they couldn't reflect the Sun, but they still could see some part of the sky and reflect it. The sky is a big thing so it's hard to block all of it!

|

|

|

|

May 16 2013, 07:56 PM May 16 2013, 07:56 PM

Post

#11

|

|

Senior Member     Group: Members Posts: 2429 Joined: 30-January 13 From: Penang, Malaysia. Member No.: 6853 |

I am sure this wheel debate will roll on for some time (pun not really intended). I have not found the specification for the material for the rover wheels, but judging from the number of dings in the rims we know the material is very ductile, but it appears to be a high performance aluminium alloy. Reassuringly aluminium remains ductile even at extremely low temperatures, but good to see that drives have occurred at mid day when the temperature ranges reduce any fatigue issues created by very low temperatures.

I would not be concerned with small punctures in the rims, after all we already have the 'Morse Code' cut outs, nor would I be concerned with a plethora of additional dings that we can expect during the remainder of its mission, but am concerned about possible 'work hardening' of the material which over time could reduce the ductility of the material that could lead to undesirably issues. I am sure the engineering team and drive planners will remind the science team from time to time that the rover wheels are not designed as rock crushers and that we would like them to last as long as the power supply |

|

|

|

May 16 2013, 08:02 PM May 16 2013, 08:02 PM

Post

#12

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

See slide 32 in http://trs-new.jpl.nasa.gov/dspace/bitstre...4/1/12-0690.pdf

QUOTE Wheel cleats and surfaces thoroughly tested for odometry, wheel impact, functionality -- localized denting & rupture, ovalization permitted -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

May 17 2013, 09:36 PM May 17 2013, 09:36 PM

Post

#13

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

It can't be It is. That 'hole' is a dent, the stress of the dent has popped the anodized coating off the inside of the wheel and we have bare aluminum reflecting the sun. That dent isn't in shadow. Those that are can reflect the bright martian sky off them. Just because something is in shadow - it doesn't mean it can't 'see the sky'. Look at it - it's not even the same color as the terrain behind it. And even if it IS punctured - it doesn't matter. Once of the test-bed rovers at JPL had flight like wheels whilst dealing with 3x the effective weight of a real rover. The wheels were punctured, dent ridden, ripped, torn, dinged, bashed, smashed, crunched. You could put your finger thru the holes in places - you could see clean thru them. And they still worked absolutely fine. That testbed now has tougher wheels simply to deal with terrestrial gravity. The lightweight scarecrow rover has flightlike wheels. I'm not sure how long it's going to take until saying 'the wheels are fine' before it gets boring. Infact, I think it might already have passed. |

|

|

|

May 17 2013, 10:01 PM May 17 2013, 10:01 PM

Post

#14

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

|

|

|

|

May 17 2013, 10:01 PM May 17 2013, 10:01 PM

Post

#15

|

|

Senior Member     Group: Members Posts: 1619 Joined: 12-February 06 From: Bergerac - FR Member No.: 678 |

Okay Doug, thanks for this very clear explanation

-------------------- |

|

|

|

May 18 2013, 03:10 PM May 18 2013, 03:10 PM

Post

#16

|

|

Senior Member     Group: Members Posts: 4247 Joined: 17-January 05 Member No.: 152 |

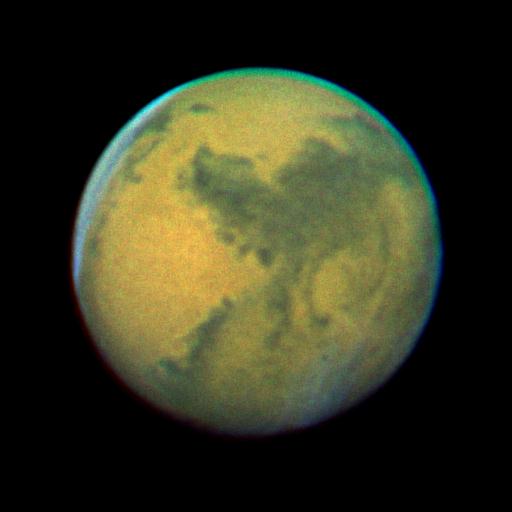

Once of the test-bed rovers at JPL had flight like wheels whilst dealing with 3x the effective weight of a real rover. The wheels were punctured, dent ridden, ripped, torn, dinged, bashed, smashed, crunched. You could put your finger thru the holes in places - you could see clean thru them. And they still worked absolutely fine. Here's a pic showing the VSTB rover with that damage. Worth a thousand words. |

|

|

|

May 18 2013, 04:04 PM May 18 2013, 04:04 PM

Post

#17

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

|

|

|

|

May 18 2013, 08:24 PM May 18 2013, 08:24 PM

Post

#18

|

|

Senior Member     Group: Members Posts: 1465 Joined: 9-February 04 From: Columbus OH USA Member No.: 13 |

Good thing Mars surface gravity is only 0.38g.

-------------------- |

|

|

|

May 18 2013, 08:57 PM May 18 2013, 08:57 PM

Post

#19

|

|

|

Newbie  Group: Members Posts: 14 Joined: 7-January 13 Member No.: 6832 |

Given the level of damage observed so far on the rover wheels and the small distance traveled, if you linearly extrapolate future damage vs distance traveled, how far can the rover drive before a wheel fails? I know no one can answer that but I would assume modeling is being done to try to answer that question??

I would also assume the rover drives will be planned to avoid sharp rocks whenever possible? |

|

|

|

May 18 2013, 09:27 PM May 18 2013, 09:27 PM

Post

#20

|

|

|

Newbie  Group: Members Posts: 7 Joined: 21-August 12 Member No.: 6598 |

It is. That 'hole' is a dent, the stress of the dent has popped the anodized coating off the inside of the wheel and we have bare aluminum reflecting the sun. That dent isn't in shadow. Those that are can reflect the bright martian sky off them. Just because something is in shadow - it doesn't mean it can't 'see the sky'. Look at it - it's not even the same color as the terrain behind it. And even if it IS punctured - it doesn't matter. Once of the test-bed rovers at JPL had flight like wheels whilst dealing with 3x the effective weight of a real rover. The wheels were punctured, dent ridden, ripped, torn, dinged, bashed, smashed, crunched. You could put your finger thru the holes in places - you could see clean thru them. And they still worked absolutely fine. That testbed now has tougher wheels simply to deal with terrestrial gravity. The lightweight scarecrow rover has flightlike wheels. I'm not sure how long it's going to take until saying 'the wheels are fine' before it gets boring. Infact, I think it might already have passed. I certainly don't know the coating or type of specific anodizing used, but anodizing in general is not a coating that can be "popped" off. Anodizing involves an etching process process to create a sponge-like texture into the metal. Dyes or other other additives are infused into the spongy porous surface of the metal. Could the anodized metal have a coating applied over it? Sure. I would rather suspect that a gouge in the metal which removed the anodized metal to expose the un-anodized surface. -J |

|

|

|

May 18 2013, 09:32 PM May 18 2013, 09:32 PM

Post

#21

|

|

|

Senior Member     Group: Members Posts: 2086 Joined: 13-February 10 From: Ontario Member No.: 5221 |

Good thing there's no shortage of soft surfaces on the way to Mt. Sharp. The dune fields are looking inviting, ironically (obviously we haven't seen them from the surface yet so pure speculation on what they're like).

|

|

|

|

May 19 2013, 01:00 AM May 19 2013, 01:00 AM

Post

#22

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

I certainly don't know the coating or type of specific anodizing used, but anodizing in general is not a coating that can be "popped" off. Anodizing is an electrochemical process whereby the top layer of aluminum is converted to alumina (AlO2) -- http://en.wikipedia.org/wiki/Anodizing There are several types and they tend to produce different thicknesses of alumina. In my experience, you can get a thin layer to pop off if you work at it, but I suspect that these dents are just specular highlights off the intact anodizing, since the black anodizing is not very matte. -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

May 19 2013, 01:08 AM May 19 2013, 01:08 AM

Post

#23

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

Given the level of damage observed so far on the rover wheels and the small distance traveled, if you linearly extrapolate future damage vs distance traveled, how far can the rover drive before a wheel fails? I would also assume the rover drives will be planned to avoid sharp rocks whenever possible? It's not really a linear process. The tire is one solid piece of aluminum. It would have to be ripped all the way across so it started unpeeling from the flexures before driving would be impeded. Like the viewgraphs I linked to earlier said, localized rupture in the tire was expected. We're talking about sharp pebbles, I don't think driving around them would be feasible. -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

May 19 2013, 01:10 AM May 19 2013, 01:10 AM

Post

#24

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

Doug has seen the damaged VSTB wheels in person and I haven't, so he's in a better position than me to know if the anodizing is actually broken off or not.

-------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

May 19 2013, 01:15 AM May 19 2013, 01:15 AM

Post

#25

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

|

|

|

|

May 19 2013, 01:46 AM May 19 2013, 01:46 AM

Post

#26

|

|

|

Senior Member     Group: Members Posts: 2998 Joined: 30-October 04 Member No.: 105 |

The likely failure point will not be on the wheel tread surface itself, but at the annulus on the inner surface where the wheel spokes attach to the wheel.

--Bill -------------------- |

|

|

|

May 19 2013, 02:18 AM May 19 2013, 02:18 AM

Post

#27

|

||

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

The likely failure point will not be on the wheel tread surface itself, but at the annulus on the inner surface where the wheel spokes attach to the wheel. I'm not following your reasoning; the entire tire is one piece of aluminum, beefed up where the flexures attach. Maybe the slide I referenced will be useful. -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

||

May 19 2013, 04:42 AM May 19 2013, 04:42 AM

Post

#28

|

|

|

Senior Member     Group: Members Posts: 1044 Joined: 17-February 09 Member No.: 4605 |

Cool design. Wheels are NOT a likely failure mode. How many ways need this be said before the subject is dropped?

|

|

|

|

May 19 2013, 05:31 AM May 19 2013, 05:31 AM

Post

#29

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

|

|

|

|

May 20 2013, 02:12 AM May 20 2013, 02:12 AM

Post

#30

|

|

|

Senior Member     Group: Members Posts: 1583 Joined: 14-October 05 From: Vermont Member No.: 530 |

|

|

|

|

May 20 2013, 03:57 AM May 20 2013, 03:57 AM

Post

#31

|

|

Administrator     Group: Admin Posts: 5172 Joined: 4-August 05 From: Pasadena, CA, USA, Earth Member No.: 454 |

OK, that was pretty funny.

-------------------- My website - My Patreon - @elakdawalla on Twitter - Please support unmannedspaceflight.com by donating here.

|

|

|

|

May 20 2013, 04:03 AM May 20 2013, 04:03 AM

Post

#32

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

Yup - hats off to that one

|

|

|

|

May 20 2013, 11:54 AM May 20 2013, 11:54 AM

Post

#33

|

|

|

Forum Contributor     Group: Members Posts: 1372 Joined: 8-February 04 From: North East Florida, USA. Member No.: 11 |

|

|

|

|

Oct 7 2013, 02:33 AM Oct 7 2013, 02:33 AM

Post

#34

|

|

|

Junior Member   Group: Members Posts: 43 Joined: 13-June 08 Member No.: 4206 |

The MER and MSL builders got a lot of things right when they put them together. I'll assume they know what they're doing with the wheels.

Correct me if I'm wrong: I understand the punctured aluminum is little more than soda can thickness and provides little or no structure strength. I understand the cleats are considerably thicker and beefier and it is these that provide shape and strength. I understand that the wheel motors are insanely high torque and could rotate the wheels if they were triangular shape. I also assume that the wheels (initially with full undamaged surface area) would tend to float on dust and other lightly packed terrain. This I assume will change over time as the thin aluminum gets punched out and ripped up. Now you have less surface area, and the cleats will tend to sink more easily in sand. And at the same time, this digging-in would provide excellent traction. And perhaps even better traction when challenged against more rocky material. Make no mistake, I was horrified to read about this! But if what I said is true, and I'm right, and the builders did their job, then there's nothing to worry over. |

|

|

|

Oct 7 2013, 08:35 PM Oct 7 2013, 08:35 PM

Post

#35

|

|

|

Member    Group: Members Posts: 153 Joined: 4-May 11 From: Pardubice, CZ Member No.: 5979 |

One question related to this topic, ... I hope.

As far as we know MER wheels are made of Aluminium 7075-T7351. Could anybody confirm MSL wheels are the same alloy? Thx. |

|

|

|

Oct 10 2013, 07:35 AM Oct 10 2013, 07:35 AM

Post

#36

|

|

|

Senior Member     Group: Members Posts: 2346 Joined: 7-December 12 Member No.: 6780 |

|

|

|

|

Oct 10 2013, 01:32 PM Oct 10 2013, 01:32 PM

Post

#37

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

I also assume that the wheels (initially with full undamaged surface area) would tend to float on dust and other lightly packed terrain. This I assume will change over time as the thin aluminum gets punched out and ripped up.... Remember - the wheels were built with several large holes in them....that spell JPL in morse code. They make little to no difference to traction or surface pressure. Remember - it's 899kg across 6 wheels each with basically the same surface contact patch. It wont change significantly with a few dings and dents in it. However - your conclusion "the builders did their job, then there's nothing to worry over" is 100% accurate. |

|

|

|

Oct 16 2013, 10:48 AM Oct 16 2013, 10:48 AM

Post

#38

|

|

|

Member    Group: Members Posts: 282 Joined: 18-June 04 Member No.: 84 |

|

|

|

|

Oct 18 2013, 11:16 PM Oct 18 2013, 11:16 PM

Post

#39

|

|

|

Member    Group: Members Posts: 105 Joined: 27-August 05 Member No.: 479 |

Remember - the wheels were built with several large holes in them....that spell JPL in morse code. They make little to no difference to traction or surface pressure. Remember - it's 899kg across 6 wheels each with basically the same surface contact patch. It wont change significantly with a few dings and dents in it. However - your conclusion "the builders did their job, then there's nothing to worry over" is 100% accurate. I would love to see the machinery used to fabricate the wheels |

|

|

|

Oct 19 2013, 01:42 AM Oct 19 2013, 01:42 AM

Post

#40

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

Go to any aerospace grade machine shop.

|

|

|

|

Oct 19 2013, 08:24 AM Oct 19 2013, 08:24 AM

Post

#41

|

|

|

Member    Group: Members Posts: 153 Joined: 4-May 11 From: Pardubice, CZ Member No.: 5979 |

Or visit directly Next Intent where they produced all MSL and MER wheels http://www.nextintent.com/portfolio-2.

|

|

|

|

Nov 25 2013, 03:21 PM Nov 25 2013, 03:21 PM

Post

#42

|

|

|

Senior Member     Group: Members Posts: 2346 Joined: 7-December 12 Member No.: 6780 |

|

|

|

|

Nov 25 2013, 04:29 PM Nov 25 2013, 04:29 PM

Post

#43

|

|

Administrator     Group: Admin Posts: 5172 Joined: 4-August 05 From: Pasadena, CA, USA, Earth Member No.: 454 |

Wow.

-------------------- My website - My Patreon - @elakdawalla on Twitter - Please support unmannedspaceflight.com by donating here.

|

|

|

|

Nov 25 2013, 05:13 PM Nov 25 2013, 05:13 PM

Post

#44

|

|

Member    Group: Members Posts: 404 Joined: 5-January 10 Member No.: 5161 |

|

|

|

|

Nov 28 2013, 12:53 PM Nov 28 2013, 12:53 PM

Post

#45

|

|

|

Senior Member     Group: Members Posts: 2346 Joined: 7-December 12 Member No.: 6780 |

Sol 469-471 Update On Curiosity From USGS Scientist Ken Herkenhoff: Tearing on Wheels

QUOTE There was some concern about tears in the rover wheels, but today we got the go-ahead to drive, with no restrictions on distance or drive mode. The tears in the wheels were expected based on testing, and the wheels are designed to survive such damage without affecting mobility. ...

|

|

|

|

Nov 28 2013, 04:56 PM Nov 28 2013, 04:56 PM

Post

#46

|

|

|

Forum Contributor     Group: Members Posts: 1372 Joined: 8-February 04 From: North East Florida, USA. Member No.: 11 |

Well there you go, if the team were concerned about the wheels, then all of our concerns were validated.

Happy Thanksgiving by the way, to those that are celebrating it. |

|

|

|

Nov 28 2013, 05:10 PM Nov 28 2013, 05:10 PM

Post

#47

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

if the team were concerned about the wheels, then all of our concerns were validated. In my experience, science teams are no more immune to having concerns about things outside their area of expertise than any other group. -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

Nov 28 2013, 05:18 PM Nov 28 2013, 05:18 PM

Post

#48

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

Well there you go, if the team were concerned about the wheels, then all of our concerns were validated. Sharing a concern doesn't in any way validate it. And just to repeat ( because seemingly it does bear repeating ) there is nothing to be concerned about. This is expected. It doesn't damage the rovers mobility. Concerns about wheel damage are not..repeat NOT valid. |

|

|

|

Nov 29 2013, 06:39 PM Nov 29 2013, 06:39 PM

Post

#49

|

|

|

Member    Group: Members Posts: 239 Joined: 28-October 12 Member No.: 6732 |

Are there any papers on MSL wheel design trade-offs?

|

|

|

|

Nov 29 2013, 06:59 PM Nov 29 2013, 06:59 PM

Post

#50

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

Are there any papers on MSL wheel design trade-offs? Did you read the viewgraph package referenced in http://www.unmannedspaceflight.com/index.p...st&p=200198 ? Other than that, I don't know of anything. There are some useful quotes in http://news.discovery.com/space/rough-rovi...tear-130522.htm (from May 2013) QUOTE “The wear in the wheels is expected,” Matt Heverly, lead rover driver for the MSL mission at NASA’s Jet Propulsion Laboratory (JPL) in Pasadena, Calif., told Discovery News via email. “The ‘skin’ of the wheel is only 0.75mm thick and we expect dents, dings, and even a few holes due to the wheels interacting with the rocks.” -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

Nov 29 2013, 07:37 PM Nov 29 2013, 07:37 PM

Post

#51

|

|

|

Solar System Cartographer     Group: Members Posts: 10164 Joined: 5-April 05 From: Canada Member No.: 227 |

One way to look at this is that the cleats really do most of the work, and they are a lot more robust.

Phil -------------------- ... because the Solar System ain't gonna map itself.

Also to be found posting similar content on https://mastodon.social/@PhilStooke Maps for download (free PD: https://upload.wikimedia.org/wikipedia/comm...Cartography.pdf NOTE: everything created by me which I post on UMSF is considered to be in the public domain (NOT CC, public domain) |

|

|

|

Nov 29 2013, 09:33 PM Nov 29 2013, 09:33 PM

Post

#52

|

|

|

Senior Member     Group: Members Posts: 1044 Joined: 17-February 09 Member No.: 4605 |

So one can posit a scenario where rather than picking up a rock in the wheel as did Spirit, as the skin of the wheel deteriorates Curiosity could pick up a rock jammed between cleats. Wouldn't stop operation but would make for amusing comments.

|

|

|

|

Nov 29 2013, 09:38 PM Nov 29 2013, 09:38 PM

Post

#53

|

|

|

Senior Member     Group: Members Posts: 2086 Joined: 13-February 10 From: Ontario Member No.: 5221 |

Who says MSL has no sample cache...

|

|

|

|

Nov 30 2013, 08:55 AM Nov 30 2013, 08:55 AM

Post

#54

|

|

|

Member    Group: Members Posts: 239 Joined: 28-October 12 Member No.: 6732 |

It would be interesting to know what other wheel options and materials they considered. What role has the function as the landing gear pads played in the wheel design?

|

|

|

|

Nov 30 2013, 01:01 PM Nov 30 2013, 01:01 PM

Post

#55

|

|

|

Member    Group: Members Posts: 153 Joined: 4-May 11 From: Pardubice, CZ Member No.: 5979 |

It would be interesting to know what other wheel options and materials they considered. I'm wondering what is the weight penalty by 2nd set of VSTB wheels with doubled skin thickness. I guess that using 1,5 mm thick skin instead of 0,75 mm actually used on Mars would eliminate most of wear we see, stop all timorous comments around and would not hurt total rover mass budget significantly. ... maybe for Mars rover 2020. |

|

|

|

Nov 30 2013, 08:13 PM Nov 30 2013, 08:13 PM

Post

#56

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

and would not hurt total rover mass budget significantly. Well - the wheel rim itself would way about twice as much. I've held one. They're not 'heavy' but there's certainly a few KG's in there. And you're forgetting - compliance in the wheel is one of the design requirements to take the edge of impacts as wheels drop off rocks etc. Making it 'stronger' just so it doesn't get holes in it ( holes that don't matter ) could very well be counter productive. Why would you change the design for 2020. They work. They work great. There's nothing whatsoever to suggest they're going to stop working. Why would you invest a second of time, energy, or money - or mass budget - in making them unnecessarily heavier? |

|

|

|

Nov 30 2013, 10:30 PM Nov 30 2013, 10:30 PM

Post

#57

|

|

|

Member    Group: Members Posts: 153 Joined: 4-May 11 From: Pardubice, CZ Member No.: 5979 |

Why would you invest .... If she's gonna work 14+ years and 2020 rover is equiped with the same wheels we'll go nuts from reading endless comments about 'weak torn wheels'. PS: I talked about doubled 'skin' thickness only (0,75 -> 1,0~1,5 mm), not to strenghten all design elements as radial and axial ribs => for sure not doubled rim weight and less elastic 'wheel-bumper' PS2: I fully trust engineers that they've made the best optimal design in compliance to all spec and that mobility won't be limited by wheels anytime during prime or future mission extensions. |

|

|

|

Nov 30 2013, 11:47 PM Nov 30 2013, 11:47 PM

Post

#58

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

|

|

|

|

Dec 1 2013, 12:13 AM Dec 1 2013, 12:13 AM

Post

#59

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

Why would you invest a second of time, energy, or money - or mass budget - in making them unnecessarily heavier? I'll confess that I've made minor engineering changes just to stop baseless concerns, so let's look at the details. If the wheels are 0.5m in diameter and 0.4m wide, then roughly speaking the outer surface volume is pi*0.5**2*0.4*0.75e-3 = 235 cm3 and its mass (aluminum density is about 2.7 gm/cm3) would be about 600 grams. Doubling the thickness would increase the mass to about 1.2 kg per wheel (times six of course) so the overall mass increase would be about 3.6 kg -- nearly twice the mass (for example) of two Mastcam camera heads. [edit: of course each wheel's mass is greater than 600 gm, this is just a rough cylindrical approximation of the mass of the 0.75mm "skin" of the wheel. For reference, 0.75mm is about 7x thicker than a typical Coke can.] However, I don't see much evidence that anyone actually read the viewgraphs I linked to. It's worth remembering that unlike MER, MSL relies on the wheels to absorb not only driving loads but landing shock, and the wheels may have to elastically deform a fair bit in the process. Making the wheels thicker would reduce their ability to do so; I'm not sure by how much, but it could be a concern. -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

Dec 1 2013, 02:08 AM Dec 1 2013, 02:08 AM

Post

#60

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

And you're forgetting - compliance in the wheel is one of the design requirements to take the edge of impacts as wheels drop off rocks etc. Making it 'stronger' just so it doesn't get holes in it ( holes that don't matter ) could very well be counter productive. I don't see much evidence that anyone actually read the viewgraphs I linked to. It's worth remembering that unlike MER, MSL relies on the wheels to absorb not only driving loads but landing shock, and the wheels may have to elastically deform a fair bit in the process. Making the wheels thicker would reduce their ability to do so; I'm not sure by how much, but it could be a concern. Well - I did ;-) |

|

|

|

Dec 1 2013, 03:00 AM Dec 1 2013, 03:00 AM

Post

#61

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

-------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

Dec 4 2013, 01:04 PM Dec 4 2013, 01:04 PM

Post

#62

|

|

|

Senior Member     Group: Members Posts: 2346 Joined: 7-December 12 Member No.: 6780 |

Sol 472-473 Update On Curiosity From USGS Scientist Ken Herkenhoff: Watching the Wheels:

QUOTE Such images of the wheels are now planned more frequently, to assess possible changes in the tears in the wheels. Besides monitoring, whether there ever could occur wheel damage justifying some concern: Can wheel "damage" be quantified in a way, such that the wheels can be interpreted as an additional mechanical science instrument to retrieve some statistics about an appropriate physical/geological property of the traversed surface? |

|

|

|

Dec 4 2013, 02:04 PM Dec 4 2013, 02:04 PM

Post

#63

|

|

Member    Group: Members Posts: 562 Joined: 29-March 05 Member No.: 221 |

Yes it can and just such an experiement was done using the Sojourner Rover. It was called the Wheel Abrasion Experiment (WAE). Thin films of different metals were emplaced on the right centre wheel. A photovoltaic cell was used to periodically measure the reflectivity and record the level of abrasion thus characterizing the surface properties.

|

|

|

|

Dec 4 2013, 02:35 PM Dec 4 2013, 02:35 PM

Post

#64

|

|

|

Senior Member     Group: Members Posts: 2346 Joined: 7-December 12 Member No.: 6780 |

Thanks a lot! So there is a good chance, that we get additional science benefit from the wheel monitoring.

|

|

|

|

Dec 4 2013, 02:46 PM Dec 4 2013, 02:46 PM

Post

#65

|

|

Senior Member     Group: Members Posts: 2492 Joined: 15-January 05 From: center Italy Member No.: 150 |

A small question: could the recent wheel status worsening be related to the long, high average speed drive on Sol 472?

-------------------- I always think before posting! - Marco -

|

|

|

|

Dec 4 2013, 03:12 PM Dec 4 2013, 03:12 PM

Post

#66

|

|

|

Solar System Cartographer     Group: Members Posts: 10164 Joined: 5-April 05 From: Canada Member No.: 227 |

No - 472 was the last drive, so we have not seen any MAHLI images since then. The 472 images are from before the drive.

Phil -------------------- ... because the Solar System ain't gonna map itself.

Also to be found posting similar content on https://mastodon.social/@PhilStooke Maps for download (free PD: https://upload.wikimedia.org/wikipedia/comm...Cartography.pdf NOTE: everything created by me which I post on UMSF is considered to be in the public domain (NOT CC, public domain) |

|

|

|

Dec 4 2013, 03:41 PM Dec 4 2013, 03:41 PM

Post

#67

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

A small question: could the recent wheel status worsening be related to the long, high average speed drive on Sol 472? There's no such thing as a 'high speed drive'. When in motion the rover is typically at the same speed. 3cm/sec. What you're perceiving as 'high speed' is a blind-drive ( no stops ) compared to autonav ( many freqent stops ) The speed of the rover when in motion is the same regardless. Go look at some speed plots at http://curiositylog.com/ to see the typical speed over time of the rover. |

|

|

|

Dec 4 2013, 04:41 PM Dec 4 2013, 04:41 PM

Post

#68

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

we get additional science benefit from the wheel monitoring. I would hesitate to call this science. At best we get a crude idea about rock size statistics, cruder I expect than what you could get just by counting rocks in images. -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

Dec 4 2013, 08:43 PM Dec 4 2013, 08:43 PM

Post

#69

|

|

Senior Member     Group: Members Posts: 2492 Joined: 15-January 05 From: center Italy Member No.: 150 |

The speed of the rover when in motion is the same regardless. Go look at some speed plots at http://curiositylog.com/ to see the typical speed over time of the rover. Thanks Phil/Doug, I already linked Joe's speed plot in my previous post, however I had the (probably wrong) impression that constant "high" speed with no stops can cause more damages! -------------------- I always think before posting! - Marco -

|

|

|

|

Dec 4 2013, 08:58 PM Dec 4 2013, 08:58 PM

Post

#70

|

|

Senior Member     Group: Members Posts: 2173 Joined: 28-December 04 From: Florida, USA Member No.: 132 |

|

|

|

|

Dec 4 2013, 09:01 PM Dec 4 2013, 09:01 PM

Post

#71

|

|

Senior Member     Group: Members Posts: 3419 Joined: 9-February 04 From: Minneapolis, MN, USA Member No.: 15 |

I doubt there is a huge amount of straight scientific data about the surface to be gleaned from examining the wheels. However, there is good engineering data about the interaction of this particular wheel design with a fairly representative Martian surface to be acquired.

There has always been a dissonance between "pure" scientific data gathering during space flights, and the acquisition of engineering data that can be useful in the design phase of the next vehicle to come along. Both are "scientific" goals, but the engineering data is used to both improve future spacecraft and to better understand and improve our engineering models (which usually led to the designs and materials being used and evaluated). Or, to put it another way, the "pure" scientific data is usually all about studying the environment we've come all this way to look at, while the engineering data is to look at the systems that got us there and keep us running so we can pursue the pure science goals. -the other Doug -------------------- “The trouble ain't that there is too many fools, but that the lightning ain't distributed right.” -Mark Twain

|

|

|

|

Dec 4 2013, 10:00 PM Dec 4 2013, 10:00 PM

Post

#72

|

|

|

Senior Member     Group: Members Posts: 1044 Joined: 17-February 09 Member No.: 4605 |

Well said Doug, and both areas of analysis are of equal importance on a mission.

|

|

|

|

Dec 4 2013, 10:16 PM Dec 4 2013, 10:16 PM

Post

#73

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

|

|

|

|

Dec 7 2013, 06:00 PM Dec 7 2013, 06:00 PM

Post

#74

|

|

|

Newbie  Group: Members Posts: 7 Joined: 21-August 12 Member No.: 6598 |

What surprises me about the wheel damage isn't the dents. That would be expected in thin aluminum. But the gaping holes are surprising to me. It's like the alloy is very brittle.

|

|

|

|

Dec 7 2013, 06:45 PM Dec 7 2013, 06:45 PM

Post

#75

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

It's like the alloy is very brittle. I assume (with no evidence to support it) that the wheels are 7075 alloy, which is somewhere near the upper end of aluminum alloys for fracture toughness -- http://en.wikipedia.org/wiki/Brittle_strength . http://en.wikipedia.org/wiki/Fracture is a useful intro to various types of fracture; see "ductile fracture". I'm not a mechanical engineer or a materials scientist and a hole is a little surprising to me too, but I'd rather see a clean hole than a big propagating rip. To anticipate a question, aluminum is less subject than say, steel, to low-temperature embrittlement. See http://www.keytometals.com/page.aspx?ID=Ch...e=ktn&NM=23 -- "Below zero, most aluminum alloys show little change in properties; yield and tensile strengths may increase; elongation may decrease slightly; impact strength remains approximately constant. Consequently, aluminum is useful material for many low-temperature applications." To sum up (note that this is all my opinion derived from public information because I've intentionally not looked at any project-internal sources on this): yes, there are holes in the wheels. Some level of wheel damage was clearly anticipated by the designers. There are a lot of tradeoffs in the MSL wheel design and it may well have not been feasible to make wheels that were impervious to puncture. Imaging the wheels is being done, presumably to assess the amount and evolution of damage. Exactly what the level of concern is, if any, is something for the project to say. -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

Dec 7 2013, 07:28 PM Dec 7 2013, 07:28 PM

Post

#76

|

|

|

Merciless Robot     Group: Admin Posts: 8784 Joined: 8-December 05 From: Los Angeles Member No.: 602 |

Given the fact that much larger holes were manufactured into the wheels for the JPL Morse tracks, my concern level is zero.

-------------------- A few will take this knowledge and use this power of a dream realized as a force for change, an impetus for further discovery to make less ancient dreams real.

|

|

|

|

Dec 7 2013, 07:50 PM Dec 7 2013, 07:50 PM

Post

#77

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

Exactly what the level of concern is, if any, is something for the project to say. Everything I've heard and read, repeatedly, states it's not a concern. There were holes in the wheels on the VSTB rover in the Mars Yard long before MSL launched. This shouldn't really be a surprise to anyone. |

|

|

|

Dec 7 2013, 09:42 PM Dec 7 2013, 09:42 PM

Post

#78

|

|

|

Senior Member     Group: Members Posts: 1044 Joined: 17-February 09 Member No.: 4605 |

So why not put this thread to bed.

|

|

|

|

Dec 7 2013, 10:06 PM Dec 7 2013, 10:06 PM

Post

#79

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

Group therapy for the morbidly pessimistic.

|

|

|

|

Dec 7 2013, 10:07 PM Dec 7 2013, 10:07 PM

Post

#80

|

|

|

Senior Member     Group: Members Posts: 3516 Joined: 4-November 05 From: North Wales Member No.: 542 |

Pictures of the wheels are great, particularly when a wheel is perched on a rock. That tells us that a particular rock is mechanically strong, unlike some of the poorly consolidated sediments around. There should be a place for posts like that. But I agree: time should be called on endless unfounded worries about the wheels.

|

|

|

|

Dec 7 2013, 10:33 PM Dec 7 2013, 10:33 PM

Post

#81

|

|

|

Newbie  Group: Members Posts: 7 Joined: 21-August 12 Member No.: 6598 |

Given the fact that much larger holes were manufactured into the wheels for the JPL Morse tracks, my concern level is zero. I was not talking about the large rectangular Morse Code holes, but the irregular large holes with jagged edges. http://www.unmannedspaceflight.com/index.p...st&id=31571 It's just surprising, that's all. I don't want to re-hash old stuff. Originally these were dismissed as glints or reflections. I just find it interesting that with 6 wide wheels with such a large contact area and reduced gravity, that one rock would be able to punch a hole in the material. I won't comment anymore. |

|

|

|

Dec 7 2013, 10:49 PM Dec 7 2013, 10:49 PM

Post

#82

|

|

|

Solar System Cartographer     Group: Members Posts: 10164 Joined: 5-April 05 From: Canada Member No.: 227 |

We get that, but the other holes show that the ones you asked about don't matter. They can't spread far because of the big cleats. It's interesting to see this but it doesn't matter.

Now let's get back to looking at the stuff you can see through the holes: Mars. Phil -------------------- ... because the Solar System ain't gonna map itself.

Also to be found posting similar content on https://mastodon.social/@PhilStooke Maps for download (free PD: https://upload.wikimedia.org/wikipedia/comm...Cartography.pdf NOTE: everything created by me which I post on UMSF is considered to be in the public domain (NOT CC, public domain) |

|

|

|

Dec 8 2013, 05:48 PM Dec 8 2013, 05:48 PM

Post

#83

|

|

|

Member    Group: Members Posts: 239 Joined: 28-October 12 Member No.: 6732 |

Why not use tires made of a titanium alloy?

|

|

|

|

Dec 8 2013, 06:17 PM Dec 8 2013, 06:17 PM

Post

#84

|

|

|

Senior Member     Group: Members Posts: 2517 Joined: 13-September 05 Member No.: 497 |

Why not use tires made of a titanium alloy? Because they would weigh more and be less compliant; the wheels are basically the only shock absorbers in the system. I have to say I feel a bit conflicted about this thread. On the one hand, some posts seem to be armchair engineering suggesting that there's something wrong with the system. On the other, some are just mostly-baseless cheerleading. I've tried to stay in between those two places by talking about the real engineering to the extent that I can, but maybe we've reached the point of diminishing returns on this topic. -------------------- Disclaimer: This post is based on public information only. Any opinions are my own.

|

|

|

|

Dec 8 2013, 07:07 PM Dec 8 2013, 07:07 PM

Post

#85

|

|

Member    Group: Members Posts: 655 Joined: 22-January 06 Member No.: 655 |

Seemingly we're not done yet. Insert heavy to industrial strength 'sigh' here. I agree with the above sentiment, and with mcaplinger and others - surely this thread beat itself to death back in the summer? If the wheels all completely fall to bits, and the rover takes an undignified nosedive into a pothole as a result, then people should feel fully justified in lambasting those who assured us that the wheels were up to the wear-and-tear. Meantime..... |

|

|

|

Dec 8 2013, 07:23 PM Dec 8 2013, 07:23 PM

Post

#86

|

|

|

Merciless Robot     Group: Admin Posts: 8784 Joined: 8-December 05 From: Los Angeles Member No.: 602 |

I think that it's safe to say that the admin/mod team has decided to keep this thread open since over time more holes will appear, and hopefully it will function as a place for people to find answers (esp. those new to UMSF), which have been graciously provided by members such as mcaplinger.

However, alarmism will not be viewed favorably, nor will criticism of the project team or designers. Engineering is all about compromise. We could have had massive wheels impervious in all respects to anything, but probably would have had to lose one or more instruments, and/or change something in the EDL methodology, and/or, and/or...it tends to snowball. The wheel design is highly robust & survivable, and it's the best compromise that could be derived based on overall system performance requirements. Enough said. -------------------- A few will take this knowledge and use this power of a dream realized as a force for change, an impetus for further discovery to make less ancient dreams real.

|

|

|

|

Dec 8 2013, 07:30 PM Dec 8 2013, 07:30 PM

Post

#87

|

|

|

Member    Group: Members Posts: 239 Joined: 28-October 12 Member No.: 6732 |

I am only asking questions to learn about the engineering design process and considered wheel options – unfortunately so far with little success.

|

|

|

|

Dec 8 2013, 07:50 PM Dec 8 2013, 07:50 PM

Post

#88

|

|

|

Merciless Robot     Group: Admin Posts: 8784 Joined: 8-December 05 From: Los Angeles Member No.: 602 |

Nobody's preventing you from doing so; again, that's what this thread is for.

My comments were not directed at anyone in particular; just wanted to define some boundaries. -------------------- A few will take this knowledge and use this power of a dream realized as a force for change, an impetus for further discovery to make less ancient dreams real.

|

|

|

|

Dec 8 2013, 08:11 PM Dec 8 2013, 08:11 PM

Post

#89

|

|

Member    Group: Members Posts: 222 Joined: 7-August 12 From: Garberville, CA Member No.: 6500 |

These stereo views seemed to go better in this thread than anywhere else. The slight axial tilt of the camera during the MAHLI surveys allows for a reasonably robust stereo image of the center wheels on either side. Here are a few recent views (with brightness levels bumped in a few to bring out some detail in the shadows) ...

...from Sol 476:   ...and from Sol 472:   (..and not to beat a dead topic, I personally think the wheels will be just fine even with a great number of holes - they have huge built in "JPL" holes - so it's hard to imagine enough damage to seriously impact the rover's mobility...) -------------------- "We shall not cease from exploration, and the end of all our exploring will be to arrive where we started and know the place for the first time." -T.S. Eliot

|

|

|

|

Dec 8 2013, 08:16 PM Dec 8 2013, 08:16 PM

Post

#90

|

|

Member    Group: Members Posts: 655 Joined: 22-January 06 Member No.: 655 |

A quick google search unearthed the following: 80+ pages of informed insight into the next generation (in which MSL is referenced) of rover wheels, and the engineering challenges/trade-offs faced by the terrain they would be exposed to. Admittedly the article references largely re-configurable wheels, but some of the challenges faced and the outcomes settled upon are instructive.

enjoy! |

|

|

|

Dec 8 2013, 08:22 PM Dec 8 2013, 08:22 PM

Post

#91

|

|||

|

Senior Member     Group: Members Posts: 2346 Joined: 7-December 12 Member No.: 6780 |

I'd like to see more emphasis on the wheels as a science instrument. Streaks, scratches, dents, holes, tears can be seen as measurements.

Here just some simplified ideas: Probably almost everyone working in mineralogy is best-familiar with determining scratch resistance or using streak plates. The frequency of scratches tells something about the abundancy of mineral grains harder than the aluminium alloy; streaks tell about cementation or about minerals softer than the alloy. More advanced are macroindentation tests, e.g. Brinell hardness tests. From known force, Brinell hardness of the wheel, and observed indentation the diameter of the indentor can be determined. The shape of indentations can e.g. be inferred from the shape of shadows. From known penetration and fracture propagation thresholds, lower bounds of the loads causing penetration can be inferred. From the driven distance the frequency per mars surface area can be calculated. So there are quantifyable data. Monitored wheel data could e.g. be used to cross-check a simulation of the mission. (Both images are regions of sol 476 MAHLI images, credit: NASA/JPL-Caltech/MSSS) |

||

|

|

|||

Dec 8 2013, 08:58 PM Dec 8 2013, 08:58 PM

Post

#92

|

|

|

Senior Member     Group: Members Posts: 1583 Joined: 14-October 05 From: Vermont Member No.: 530 |

|

|

|

|

Dec 8 2013, 09:28 PM Dec 8 2013, 09:28 PM

Post

#93

|

|

|

Senior Member     Group: Members Posts: 2346 Joined: 7-December 12 Member No.: 6780 |

The very surface will be oxidized.

I've mainly been referring to the metal below the oxidized layer, which M.Caplinger suspected to be 7075 aluminium alloy, consisting of aluminium, zinc, magnesium, and copper. Pure aluminium is rarely used. Remains the question about the scratch resistance of the oxide layer. |

|

|

|

Dec 9 2013, 02:08 AM Dec 9 2013, 02:08 AM

Post

#94

|

|

|

Senior Member     Group: Members Posts: 1044 Joined: 17-February 09 Member No.: 4605 |

Well you are certainly thinking well outside the box there Gerald and full marks for that although I honestly cannot see any real utility in your suggestion. I guess that the hardness of the anodized layer will have been assessed although you would be pretty safe thinking it to be 7 < <9 (MOHS). Basalt has a MOHS of around 7 but the punctures in the wheel would be caused by small cross sectional contact where the effect on the basalt would be compression. There is no real time visual monitoring so no information available on when or where an incident (scratch, rear, puncture or crazing) occurred, or the dynamics. The anodized coating will have a different coefficient of thermal expansion than the underlying aluminium so there could be a degree of crazing caused by the Martian temperature variations which at the image resolution available would muddy the waters.

|

|

|

|

Dec 9 2013, 02:39 AM Dec 9 2013, 02:39 AM

Post

#95

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

I'd like to see more emphasis on the wheels as a science instrument. Streaks, scratches, dents, holes, tears can be seen as measurements. However - we will never know what they are a measurement of. Which rock/soil/pebble etc cause what damage. I'm afraid whilst your enthusiasm for this is admirable - there really isn't a legitimate means to extract quantitative data from this. |

|

|

|

Dec 9 2013, 11:00 AM Dec 9 2013, 11:00 AM

Post

#96

|

|

|

Senior Member     Group: Members Posts: 2346 Joined: 7-December 12 Member No.: 6780 |

... I honestly cannot see any real utility in your suggestion ... Let me just pick out one simple hypothetical(?) example, because elaborating everything is beyond my possibilities: Imagine a green streak on a wheel. My first association would be malachite, although unlikely on Mars. The wheels can look beneath the dust all along the drive, whereas the cameras can't. If a dent is associated with the streak this may give an estimate of the shape of the peak which caused the streak, useful when driving back for detailed investigation. Here some surface parameters (to be applied to macroscopic features), which could be checked for their effect on the wheels, and possibly back-projected from wheel damage. Just to inspire people to make more of it. I'll (by default) return to monitoring/image processing. |

|

|

|

Dec 9 2013, 04:05 PM Dec 9 2013, 04:05 PM

Post

#97

|

|

|

Founder     Group: Chairman Posts: 14432 Joined: 8-February 04 Member No.: 1 |

If a dent is associated with the streak this may give an estimate of the shape of the peak which caused the streak, useful when driving back for detailed investigation. Let's say we have an 80m drive, at the end of which something like what you say is visible. Where is it? Where on the 80m drive? There's no way of knowing. moreover you can only see perhaps 40% of each wheel, possibly less, from MAHLI at the end of any particular drive. So a situation may occur where we have one of your streaks visible on the wheel....and it might have actually occurred several drives previously - several hundred meters ago. How are you going to find it. Furthermore - anything a rear wheel runs over....has already been run over twice by the wheels in front. Again - whilst your enthusiasm for this is admirable, I'm afraid it doesn't stand up to the realities of Mars, or rover ops. There will in due time, I'm sure, be papers published about how the wheels are behaving - but attempting to characterize and identify particular rocks as part of the daily planning cycle....no....it's just not practical. |

|

|

|

Dec 20 2013, 07:37 PM Dec 20 2013, 07:37 PM

Post

#98

|

|

Senior Member     Group: Members Posts: 4247 Joined: 17-January 05 Member No.: 152 |

|

|

|

|

Dec 20 2013, 09:40 PM Dec 20 2013, 09:40 PM

Post

#99

|

|

|

Senior Member     Group: Members Posts: 2831 Joined: 22-April 05 From: Ridderkerk, Netherlands Member No.: 353 |

|

|

|

|

Dec 21 2013, 02:43 AM Dec 21 2013, 02:43 AM

Post

#100

|

|

|

Member    Group: Members Posts: 866 Joined: 15-March 05 From: Santa Cruz, CA Member No.: 196 |

little punched-out shred in SOL488 image and the adjacent one as well, seems to have been pushed in quite far. soon as it falls off were doomed!!

the inside surface is rendering with some pretty convincing displacement mapping now. |

|

|

|

|

|

Lo-Fi Version | Time is now: 19th May 2024 - 03:48 PM |

|

RULES AND GUIDELINES Please read the Forum Rules and Guidelines before posting. IMAGE COPYRIGHT |

OPINIONS AND MODERATION Opinions expressed on UnmannedSpaceflight.com are those of the individual posters and do not necessarily reflect the opinions of UnmannedSpaceflight.com or The Planetary Society. The all-volunteer UnmannedSpaceflight.com moderation team is wholly independent of The Planetary Society. The Planetary Society has no influence over decisions made by the UnmannedSpaceflight.com moderators. |

SUPPORT THE FORUM Unmannedspaceflight.com is funded by the Planetary Society. Please consider supporting our work and many other projects by donating to the Society or becoming a member. |

|